EXCITING and NEW RESEARCH DEVELOPMENTS

SURFACE ROUGHNESS EFFECTS ON IMPINGEMENT JET ARRAY SURFACE HEAT TRANSFER

Surface Roughness Effects on Impingement Jet Array Surface Heat Transfer

Overall, the focus of the effort is fundamental understanding of thermal transport, and heat transfer phenomena, as altered by impingement array jets as they impact upon different target surface roughness arrangements. Applications are varied, and include electronic cooling, electronic component chip cooling, heat exchangers, utility gas turbine engines employed for power generation, micro-fluidic devices which are employed within electronic components, as well as a variety of other heat transfer augmentation devices.

A variety of different surface roughness configurations are considered, along with a smooth target plate, which is employed to provide baseline comparison data. Included are surface arrays of small rectangular roughness 1-2, small triangle roughness 3-4, small cylinder roughness 5-6, as well as surface arrays of small roughness, employed in conjunction with large pin roughness 1-6. Considered are a variety of different roughness shapes, different roughness configurations, different roughness heights, and different values of Rej, impingement jet Reynolds number.

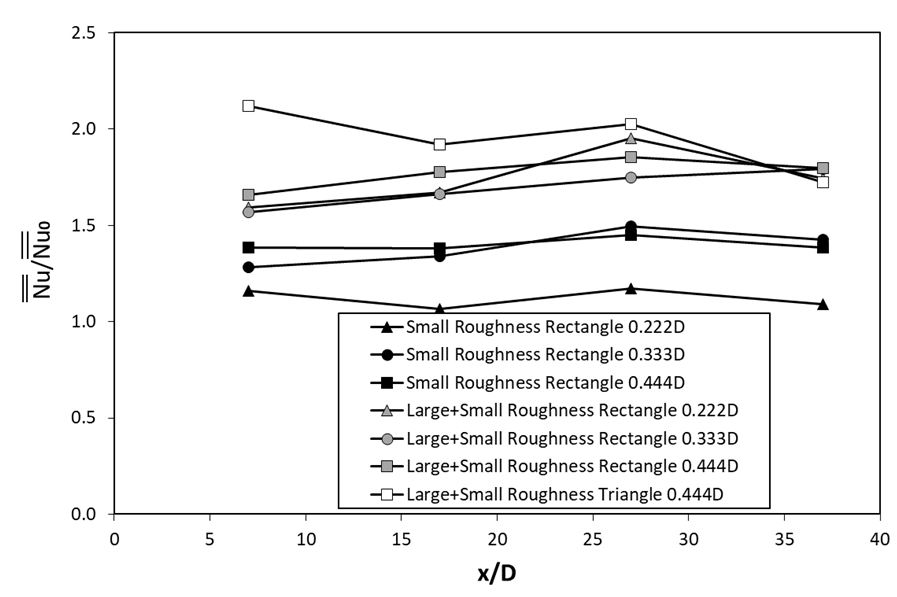

Figure 1. SPATIALLY-AVERAGED NUSSELT NUMBER RATIOS FOR DIFFERENT ROUGHNESS HEIGHTS AND DIFFERENT ROUGHNESS CONFIGURATIONS, Rej=5000, from Buzzard et al. 1,2.

An example of spatially-averaged surface Nusselt number ratios are given in Figure 1, from Buzzard et al. 1,2. Here, the baseline Nusselt numbers used for normalization of these results are obtained with impingement cooling applied to smooth target surfaces at the same experimental conditions. Note that no other baseline condition is appropriate for normalization of these impingement cooling results. The turbulent data in Figure 1 are given for rectangle small roughness, both with and without large pin roughness. Here, the jet Reynolds number is 5000. Within this figure, spatially-averaged Nusselt number ratios generally increase at each x/D location, as small roughness height increases (from 0.222D to 0.333D to 0.444D, where D is impingement hole diameter), and as large pins are added to the configurations. Such behavior results from increased local mixing and local turbulent transport, as roughness elements become higher and/or more numerous. Also important is the increase in wetted surface area, relative to a smooth target surface, which results from the addition of the different roughness elements. Note that the highest spatially-averaged Nusselt number ratios are present for a surface array of small triangle roughness with 0.444D height, with large pin roughness. With this arrangement spatially-averaged Nusselt number ratios are as high as 2.2 1,2.

RECENT PUBLICATIONS

- Impingement Jet Array Heat Transfer With Small-Scale Cylinder Target Surface Roughness Arrays, (P. M. Ligrani, Z. Ren, W. C. Buzzard), International Journal of Heat and Mass Transfer, Vol. 107, pp. 895-905, April 2017.

- Impingement Jet Array Heat Transfer: Target Surface Roughness Shape, Reynolds Number Effects, (Z. Ren, W. C. Buzzard, P. M. Ligrani, C. Nakamata, and S. Ueguchi), AIAA Journal of Thermophysics and Heat Transfer, Vol. 31, No. 2, pp. 346-357, April 2017.

- Influences of Target Surface Small-Scale Rectangle Roughness on Impingement Jet Array Heat Transfer, (W. C. Buzzard, Z. Ren, P. M. Ligrani, C. Nakamata, and S. Ueguchi), International Journal of Heat and Mass Transfer, Vol. 110, pp. 805-816, July 2017.

- Effects of Hole Shape On Impingement Jet Array Heat Transfer With Small-Scale, Target Surface Triangle Roughness (P. McInturff, M. Suzuki, P. M. Ligrani, C. Nakamata, and D. H. Lee), International Journal of Heat and Mass Transfer, Vol. 127, Part A, pp. 585-597, December 2018.

- Winglet-Pair Target Surface Roughness Influences On Impingement Jet Array Heat Transfer (P. M. Ligrani, P. McInturff, M. Suzuki, and C. Nakamata), Journal of Enhanced Heat Transfer, Vol. 26, No. 1, pp. 15-35, January 2019.

- Flow and Heat Transfer Characteristics of Micro Pin-Fins Under Jet Impingement Arrays (X. Lu, W. Li, X. Li, J. Ren, H. Jiang, and P. M. Ligrani), International Journal of Heat and Mass Transfer, Volume 143, Paper No. 118416, pp. 1-14, November 2019.