RESEARCH AREAS

– Dimple Array on Surfaces of Channels

– Investigations of Confined, Millimeter-Scale, Unsteady Laminar Impinging Slot Jets

– Aerodynamic Losses and Mixing Losses from Turbine Airfoils

– Impingement Cooling

– Internal Cooling – Surface Heat Transfer Augmentation

– Miniature and Micro-Scale Pumps

– Surface Roughness

– Electronics Cooling

– Transitional Flows in Curved Channels

– Film Cooling

– Flow and Heat Transfer on and Near a Transonic Turbine Blade Tip

– Slip Phenomina in Micro-Fluidic Devices

– Buoyancy-Driven Continuous SPLITT Fractionation: A New Technique for Separation of Microspheres

– Investigations of Full-Coverage Film Cooling

– Shock Wave Boundary Layer Interactions

– Double Wall Cooling

– Elastic Turbulence

– Surface Roughness Effects on Impingement Jet Array Surface Heat Transfer

– Dean Flow Dynamics in Low-Aspect Ratio Spiral Microchannels

Film Cooling

Dr. Phil Ligrani: p_ligrani@msn.com

- Applicable to external cooling of turbine airfoils for gas turbine engines

- Heat transfer and flow characteristics

- Effects of bulk flow pulsations

- Hole shape, hole angle, staggered and single rows of holes, supply plenum arrangement

- Effects of longitudinal vortices

- Effects of shock waves, and transonic freestream and film flows

- Effects of compressibility and variable properties

Film-cooling is widely used to cool and thereby protect turbine component surfaces from exposure to the hot gases produced in combustion chambers of high performance gas turbine engines. The protection provided by these film cooling flows is altered by a variety of physical and geometric effects. Some characteristics of these different physical effects are investigated as they affect the thermal protection nominally provided by different film cooling flows. The topics addressed are: (i) hole angle orientation (including compound angle orientations), (ii) hole shape, (iii) longitudinal vortices, (iv) bulk flow pulsations, (v) bulk flow pulsations on the vortices which form due to the interactions between the film and the external cross flows, (vi) compressibility and variable properties, (vii) shock waves, (viii) supply plenum arrangement, (ix) transonic freestream and film flow conditions, and (x) film cooling on aerodynamic mixing losses. The shaped hole configurations discussed include laterally-diffused-compound-angle holes, forward-diffused-compound-angle holes, laid-back fan-shaped holes with simple angle orientations, and laid-back fan-shaped holes with compound angle orientations. The bulk flow pulsation results (item (iv)) are tied to pulsations of static pressure and streamwise velocity, which are present in the first stages of operating transonic gas turbines due to potential flow interactions, and passing families of shock waves.

These different effects are considered as they affect film cooling performance, including local and spatially-averaged distributions of: (a) surface adiabatic film cooling effectiveness, (b) surface heat transfer coefficients, (c) surface heat flux ratios with and without film cooling, and (d) in one case, aerodynamic losses. In some cases, flow structural measurements in and outside of the film cooled boundary layers are also investigated, such as temperature fields, and flow visualizations using smoke. For topics (i)-(v), the experimental results are obtained on large-scales to obtain details of flow structure, and for topics (vi)-(x), on small scales, to simulate some of the geometries and flow conditions encountered in operating engines. The different types of results, and the different effects are related to the latest film cooling technologies employed in first turbine stages of high performance gas turbine engines used for aircraft propulsion, utility power generation, and other applications.

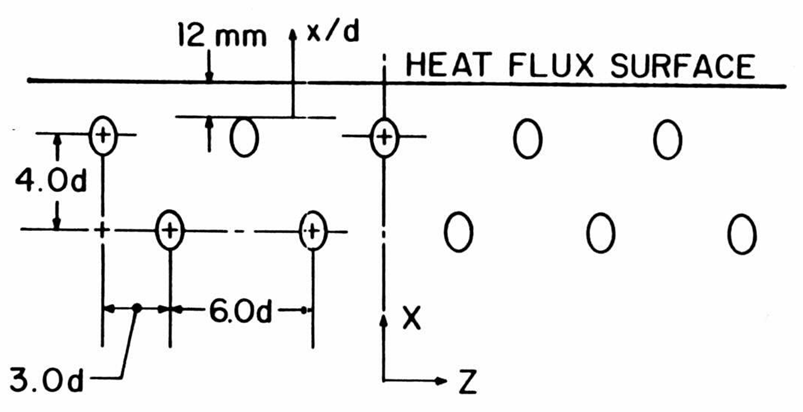

Test surface injection geometry for film cooling holes arranged with configuration 2 simple angle holes.

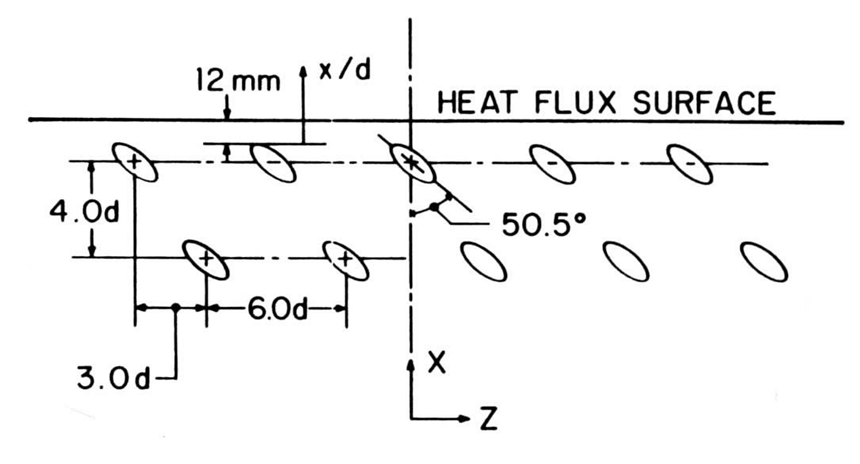

Test surface injection geometry for film cooling holes arranged with configuration 3 compound angle holes.

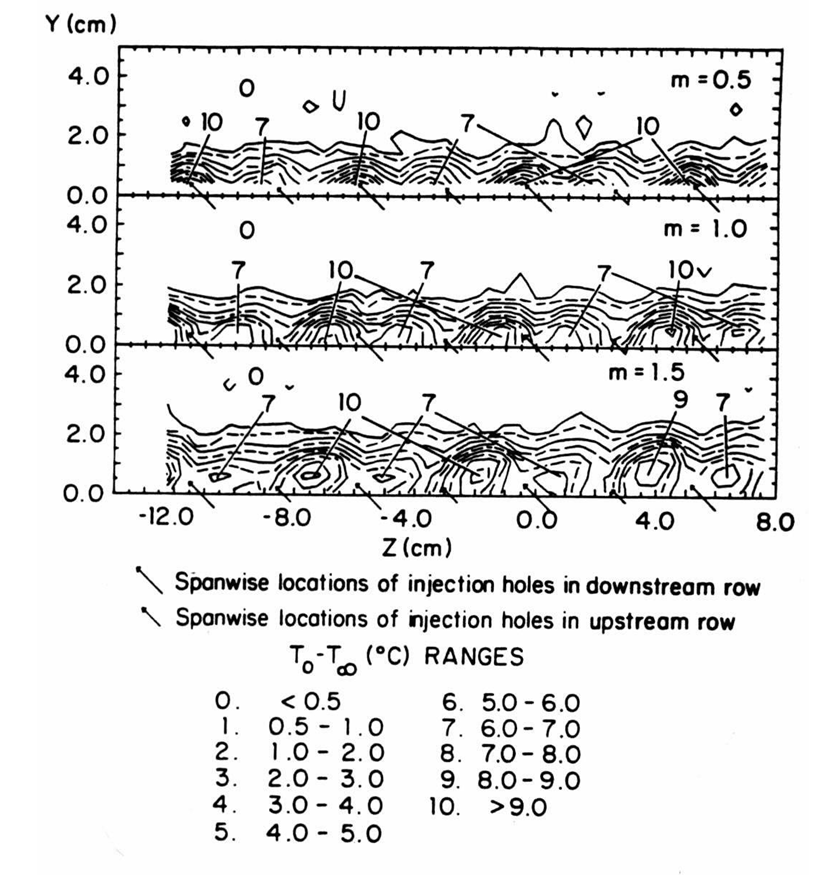

Mean temperature fields showing distributions of film injectant downstream of two rows of compound angle configuration 3 film cooling holes at x/d=9.9 for blowing ratios of 0.5, 1.0, and 1.5.

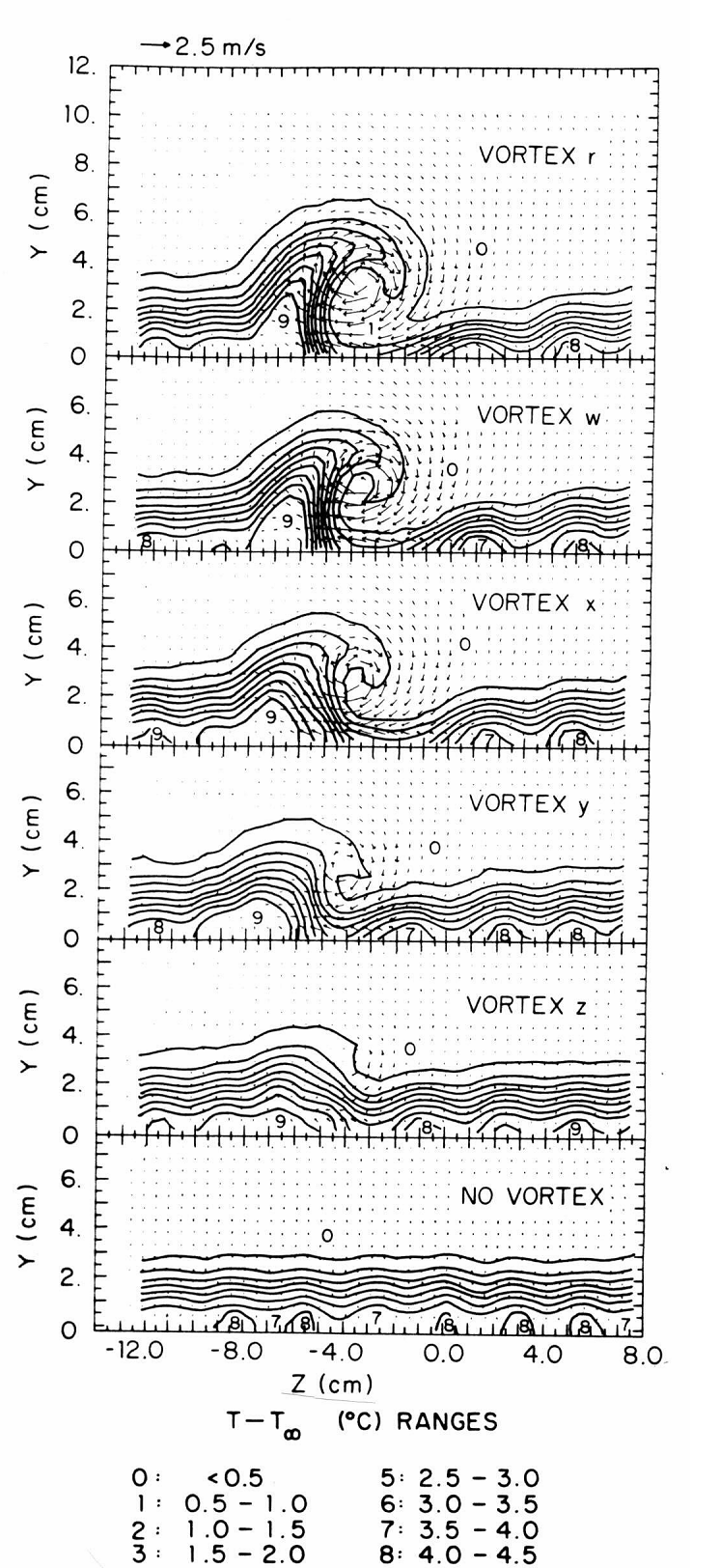

Mean temperature field showing distributions of film injectant with secondary flow vectors at x/d=41.9, a blowing ratio of 0.5, and freestream velocity of 10 m/s. Spanwise vortex position e: vortex downwash passes over the centerline injection hole.

|

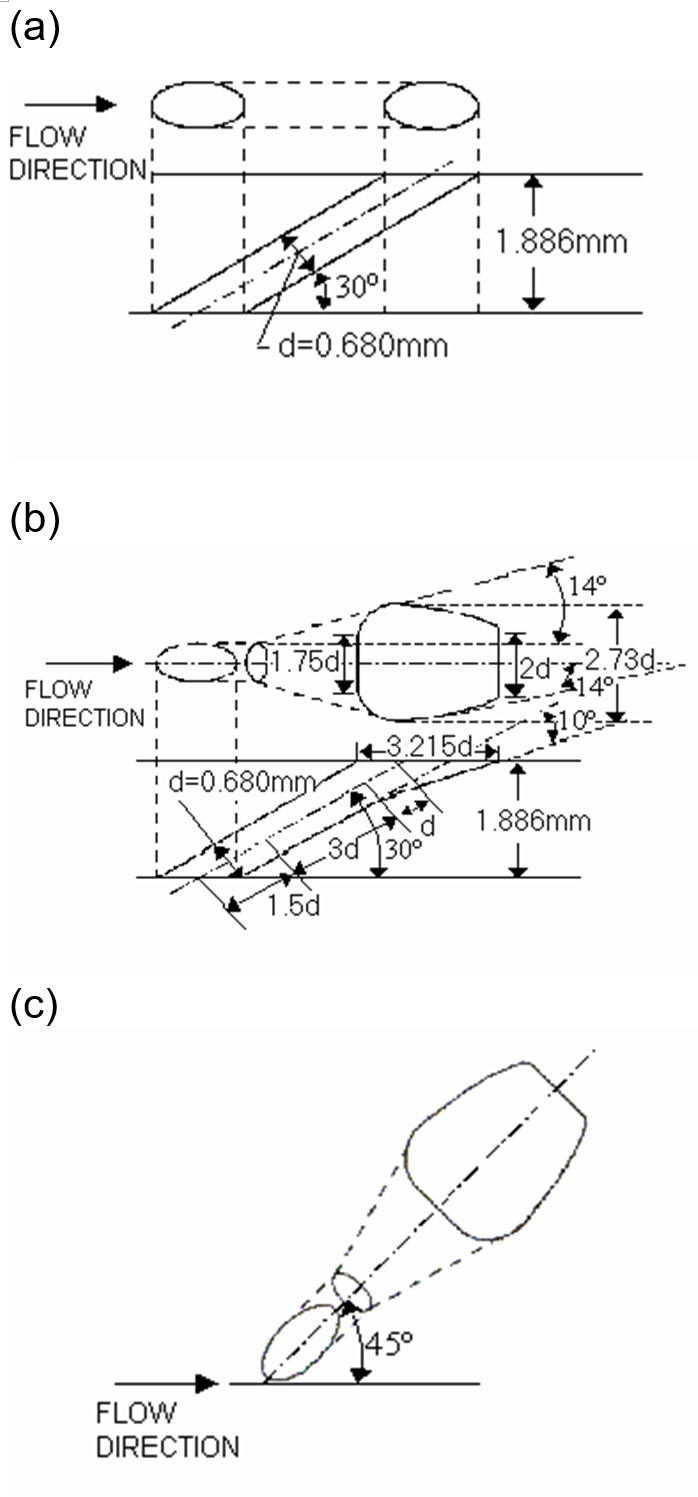

Film cooling hole geometries:

Film cooling hole geometries: (a) round, cylindrical holes with simple angle orientations (CYSA), (b) laid-back-fan-shaped holes with simple angle orientations (LBFS-SA), and (c) laid-back-fan-shaped holes with compound angle orientations (LBFS-CA). |

|

||

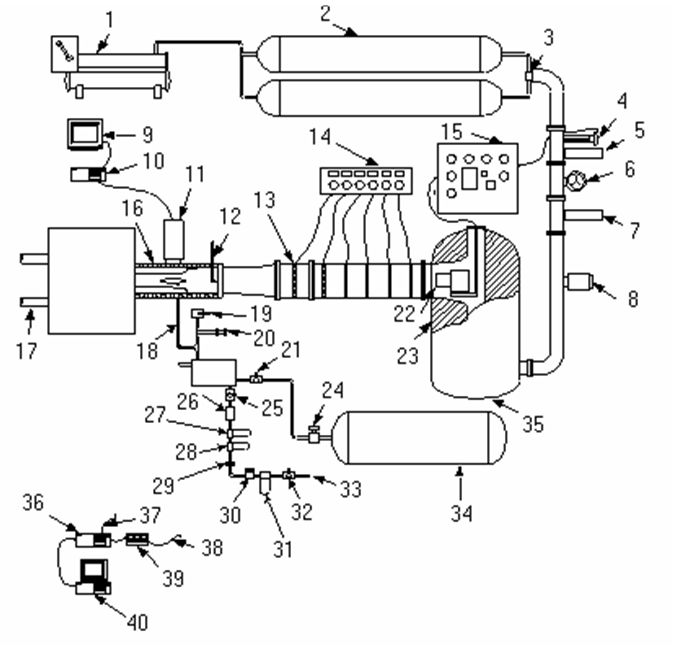

| 1. Compressor 2. Storage Tanks 3. Octopus Collection Manifold 4. Pressure Regulator 5. Pressure Releif Valve 6. Manual Valve 7. Pressure Releif Valve 8. Mass Flow Valve 9. Monitor 10. VCR 11. IR Camera 12. Pitot Tube 13. Resistance Strip Heaters 14. Strip Heater Control Panel |

15. Flow/Internal Heater Control Panel 16. Test Section 17. Outlet Piping 18. Insulated Hose 19. Manual Valve 20. Automatic Valve 21. Manual Valve 22. Resistance Heater 23. Fire Brick 24. Manual Valve 25. Manual Valve 26. Rotameter 27. Dessicant Air Dryer |

28. Coalescing Filter 29. Sonic Orifice Plate 30. Pressure Regulator 31. Particulate Filter 32. Manual Valve 33. Compressed Air Supply 34. Liquid Nitrogen Tank 35. Heater Tank 36. Data Acquisition Unit 37. Thermocouple Wires 38. Air Tubing 39. Pressure Transducers 40. Computer |

|

University of Utah Transonic Wind Tunnel (TWT) including film injection system.

|

||

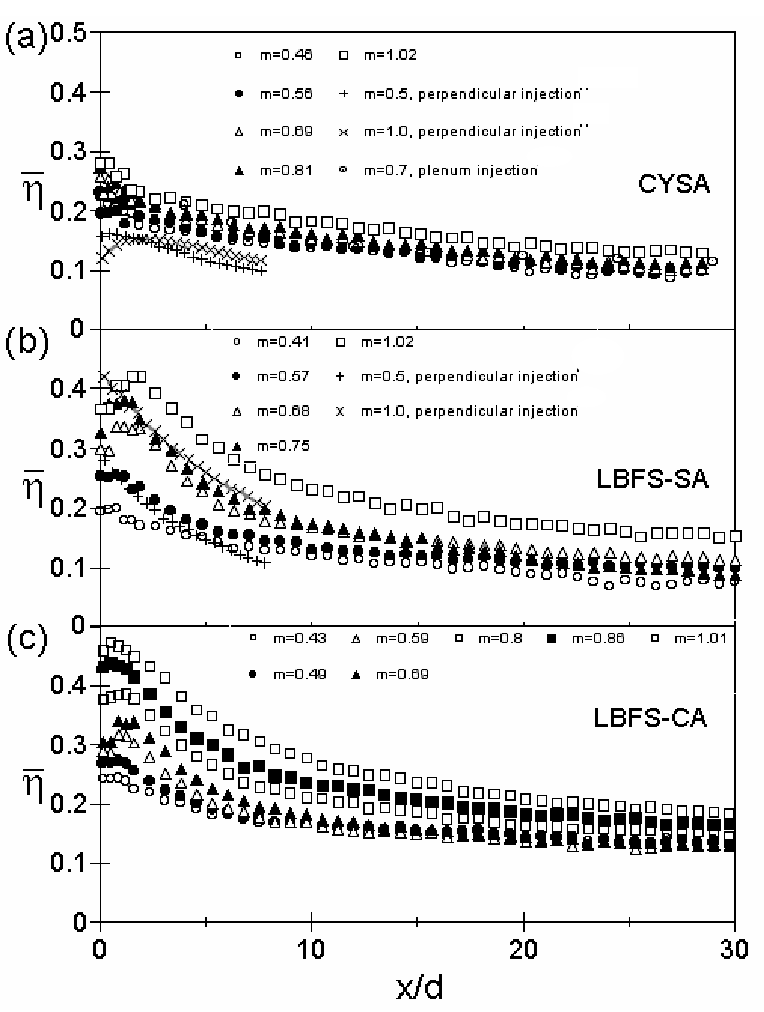

Spanwise-averaged, surface adiabatic film cooling effectiveness distributions for:

(a) round, cylindrical holes with simple angle orientations (CYSA)

(b) laid-back-fan-shaped holes with simple angle orientations (LBFS-SA)

(c) laid-back-fan-shaped holes with compound angle orientations (LBFS-CA).

RECENT PUBLICATIONS:

- Heat Transfer in Film-Cooled Turbulent Boundary Layers at Different Blowing Ratios as Affected by Longitudinal Vortices (P. M. Ligrani, S. L. Joseph, A. Ortiz, and D. L. Evans), Experimental Thermal and Fluid Science, Vol. 1, No. 4, pp. 347-362, 1988.

- Effects of Embedded Vortices on Film-Cooled Turbulent Boundary Layers (P. M. Ligrani, A. Ortiz, S. L. Joseph, and D. L. Evans), ASME Transactions-Journal of Turbomachinery, Vol. 111, No. 1, pp. 71-77, January 1989.

- Effects of an Embedded Vortex on Injectant from a Single Film-Cooling Hole in a Turbulent Boundary Layer (P. M. Ligrani and W. W. Williams), ASME Transactions-Journal of Turbomachinery, Vol. 112, No. 3, pp. 428-436, July 1990.

- Effects of Vortices with Different Circulations on Heat Transfer and Injectant Downstream of a Row of Film-Cooling Holes in a Turbulent Boundary Layer (P. M. Ligrani, C. S. Subramanian, D. W. Craig and P. Kaisuwan), ASME Transactions-Journal of Heat Transfer, Vol. 113, No. 1, pp. 79-90, February 1991.

- Effects of Vortices with Different Circulations on Heat Transfer and Injectant Downstream of a Single Film-Cooling Hole in a Turbulent Boundary Layer (P. M. Ligrani, C. S. Subramanian, D. W. Craig and P. Kaisuwan), ASME Transactions-Journal of Turbomachinery, Vol. 113, No. 3, pp. 433-441, July 1991.

- Heat Transfer, Adiabatic Effectiveness and Injectant Distributions Downstream of a Single Row and Two Staggered Rows of Compound Angle Film-Cooling Holes (P. M. Ligrani, S. Ciriello and D. T. Bishop), ASME Transactions-Journal of Turbomachinery, Vol. 114, No. 4, pp. 687-700, October 1992.

- Interactions Between Embedded Vortices and Injectant From Film Cooling Holes With Compound Angle Orientations in a Turbulent Boundary Layer (P. M. Ligrani and S. W. Mitchell), ASME Transactions-Journal of Turbomachinery, Vol. 116, No. 1, pp. 80-91, January 1994.

- Film Cooling From Holes With Compound Angle Orientations, Part 1: Results Downstream of Two Staggered Rows of Holes With 3d Spanwise Spacing (P. M. Ligrani, J. M. Wigle, S. Ciriello, and S. M. Jackson), ASME Transactions-Journal of Heat Transfer, Vol. 116, No. 2, pp. 341-352, May 1994.

- Film Cooling From Holes With Compound Angle Orientations, Part 2: Results Downstream of a Single Row of Holes With 6d Spanwise Spacing (P. M. Ligrani, J. M. Wigle, and S. M. Jackson), ASME Transactions-Journal of Heat Transfer, Vol. 116, No. 2, pp. 353-362, May 1994.

- Effects of Embedded Vortices on Injectant From Film Cooling Holes With Large Spanwise Spacing and Compound Angle Orientations in a Turbulent Boundary Layer (P. M. Ligrani and S. W. Mitchell), ASME Transactions-Journal of Turbomachinery, Vol. 116, No. 4, pp. 709-720, October 1994.

- Film Cooling From Two Staggered Rows of Compound Angle Holes at High Blowing Ratios (P. M. Ligrani and J. S. Lee), International Journal of Rotating Machinery, Vol. 2, No. 3, pp. 201-208, April 1996.

- Bulk Flow Pulsations and Film Cooling: Part 1, Injectant Behavior (P. M. Ligrani, R. Gong, J. M. Cuthrell, and J. S. Lee), International Journal of Heat and Mass Transfer, Vol. 39, No. 11, pp. 2271-2282, July 1996.

- Bulk Flow Pulsations and Film Cooling: Part 2, Flow Structure and Film Effectiveness (P. M. Ligrani, R. Gong, J. M. Cuthrell, and J. S. Lee), International Journal of Heat and Mass Transfer, Vol. 39, No. 11, pp. 2283-2292, July 1996.

- Film Cooling From a Single Row of Compound Angle Holes at High Blowing Ratios (P. M. Ligrani and J. S. Lee), International Journal of Rotating Machinery, Vol. 2, No. 4, pp. 259-267, November 1996.

- Effects of Bulk Flow Pulsations on Film-Cooled Boundary Layer Structure (P. M. Ligrani, R. Gong, J. M. Cuthrell, and J. S. Lee), ASME Transactions-Journal of Fluids Engineering, Vol. 119, No. 1, pp. 56-66, March 1997.

- Film Cooling From Spanwise-Oriented Holes in Two Staggered Rows (P. M. Ligrani and A. E. Ramsey), ASME Transactions-Journal of Turbomachinery, Vol. 119, No. 3, pp. 562-567, July 1997.

- Bulk Flow Pulsations and Film Cooling: Flow Structure Just Downstream of the Holes (P. M. Ligrani, R. Gong, and J. M. Cuthrell), ASME Transactions-Journal of Turbomachinery, Vol. 119, No. 3, pp. 568-573, July 1997.

- Film Cooling From a Single Row of Holes Oriented in Spanwise/Normal Planes (P. M. Ligrani and A. E. Ramsey), ASME Transactions-Journal of Turbomachinery, Vol. 119, No. 4, pp. 770-776, October 1997.

- The Effect of Injection Hole Length on Film Cooling With Bulk Flow Pulsations (H. J. Seo, J. S. Lee, and P. M. Ligrani), International Journal of Heat and Mass Transfer, Vol. 41, No. 22, pp. 3515-3528, November 1998.

- Film Cooling Subject to Bulk Flow Pulsations: Effects of Blowing Ratio, Freestream Velocity, and Pulsation Frequency (C. M. Bell, P. M. Ligrani, W. A. Hull, and C. M. Norton), International Journal of Heat and Mass Transfer, Vol. 42, No. 23, pp. 4333-4344, December 1999.

- Transonic Aerodynamic Losses Due to Turbine Airfoil, Suction Surface Film Cooling (D. J. Jackson, K. L. Lee, P. M. Ligrani, and P. D. Johnson), ASME Transactions-Journal of Turbomachinery, Vol. 122, No. 2, pp. 317-326, April 2000.

- Film Cooling From Shaped Holes (C. M. Bell, H. Hamakawa, and P. M. Ligrani), ASME Transactions-Journal of Heat Transfer, Vol. 122, No. 2, pp. 224-232, May 2000.

- Flow Visualization and Flow Tracking as Applied to Turbine Components in Gas Turbine Engines (P. M. Ligrani), Measurement Science and Technology (special topical issue), Vol. 11, No. 7, pp. 992-1006, July 2000.

- Film Cooling Subject to Bulk Flow Pulsations: Effects of Density Ratio, Hole Length-to-Diameter Ratio, and Pulsation Frequency (P. M. Ligrani and C. M. Bell), International Journal of Heat and Mass Transfer, Vol. 44, No. 10, pp. 2005-2009, May 2001.

- Effects of Bulk Flow Pulsations on Phase-Averaged and Time-Averaged Film-Cooled Boundary Layer Flow Structure, (I.-S. Jung, P. M. Ligrani, and J. S. Lee), ASME Transactions-Journal of Fluids Engineering, Vol. 123, No. 3, pp. 559-566, September 2001.

- Shock Wave – Film Cooling Interactions In Transonic Flows, (P. M. Ligrani, C. Saumweber, A. Schulz, and S. Wittig), ASME Transactions-Journal of Turbomachinery, Vol. 123, No. 4, pp. 788-797, October 2001.

- Effects of Bulk Flow Pulsations on Film Cooling With Compound Angle Holes: Heat Transfer Coefficient Ratio and Heat Flux Ratio, (I. S. Jung, J. S. Lee, and P. M. Ligrani), ASME Transactions-Journal of Turbomachinery, Vol. 124, No. 1, pp. 142-151, January 2002.

- Transonic Film Cooling Effectiveness From Shaped Holes on a Simulated Turbine Airfoil, (T. Fukukawa, and P. M. Ligrani), AIAA Journal of Thermophysics and Heat Transfer, Vol. 16, No. 2, pp. 228-237, April-June 2002.

- Interactions and Influences of Different Physical Effects With Film Cooling, (P. M. Ligrani), Promyshlennaya Teplotechnika, Vol. 24, No. 4, pp. 5-31, September 2002